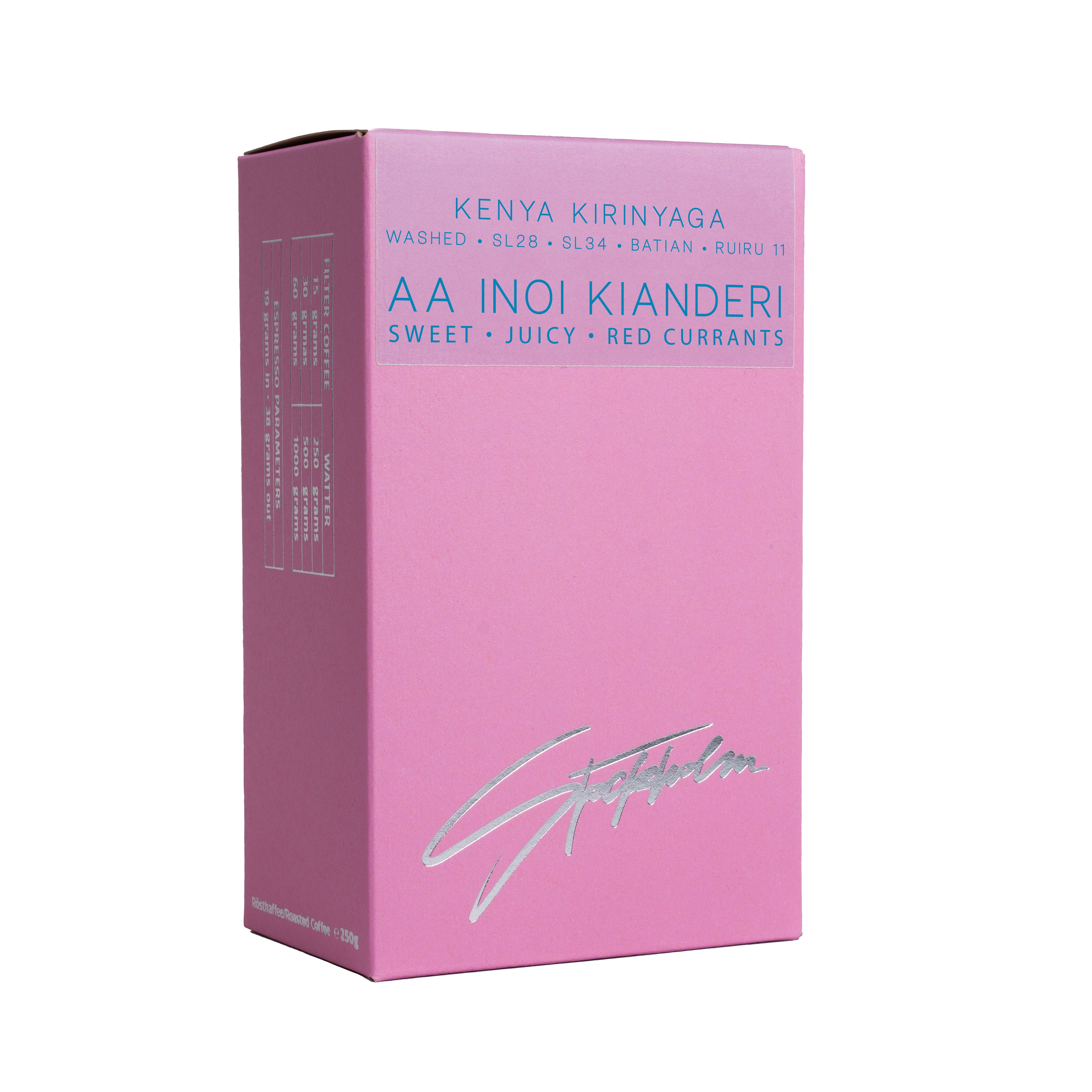

Kianderi Factory - Inoi Farmers' Cooperative Society

Nestled in the foothills of Mount Kenya, just outside Kerugoya town in Kirinyaga County, the Kianderi Factory operates as part of the Inoi Farmers' Cooperative Society. Positioned at an elevation of 1650–1800 meters above sea level, the factory processes coffee cherries supplied by 900 active smallholder farmers.

Location & Growing Conditions

Kirinyaga County is located approximately 192 kilometers northeast of Nairobi and shares borders with Nyeri and Embu Counties. The region is renowned for its ideal coffee-growing conditions, which include mineral-rich red volcanic loam soils and high altitudes. Western Kirinyaga, in particular, is celebrated for its fertile soils, making it one of the most productive coffee-growing areas in Kenya.

Coffee Cultivation

The cooperative farmers grow SL28, SL34, Batian, and Ruiru 11 coffee varieties on clay loam soils. The coffee plants flower from February to April, with the harvest season running from October to January. The region enjoys 1400 mm of annual rainfall and maintains a moderate average temperature of 20.5°C, which supports excellent coffee quality.

Processing Steps

- Delivery and Sorting:

Farmers deliver their coffee cherries to the washing station, where they are carefully hand-sorted to remove underripe, insect-damaged, and defective cherries. - Pulping and Fermentation:

After sorting, the cherries are pulped to remove the fruit layer, leaving the parchment. This parchment undergoes overnight fermentation to break down remaining mucilage. - Washing and Grading:

Post-fermentation, the parchment is washed and graded into categories: P1, P2, P3, and P light. - Drying:

The parchment is sun-dried on raised beds for 10 to 20 days, depending on weather conditions.

Sustainability Practices

After processing, the cooperative ensures sustainable practices by providing farmers with the leftover cherry pulp. Farmers mix the pulp with cow manure to create organic fertilizer, which is used to enrich their farms, promoting a cycle of sustainable coffee production.